Our Products

20 years of manufacturing experience to meet the stringent standards for the Japanese Fortune 500 companies,PC and other multi-material products customized on demand, perfectly solving the problem of material jamming on automatic machines.

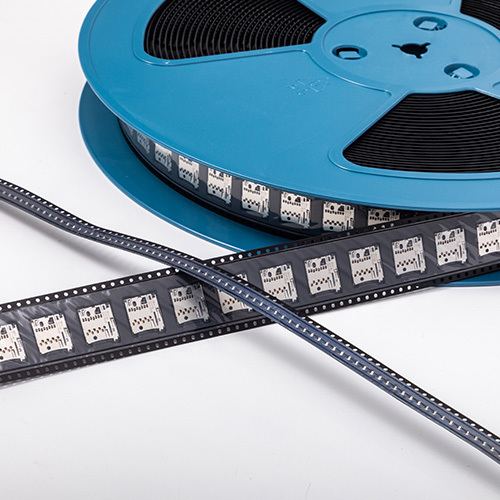

Emboss Products

The products have a sealing stability and weather resistance in strict accordance with EIA standards, and support different packaging methods such as paper reel, plastic reel and rewinding.

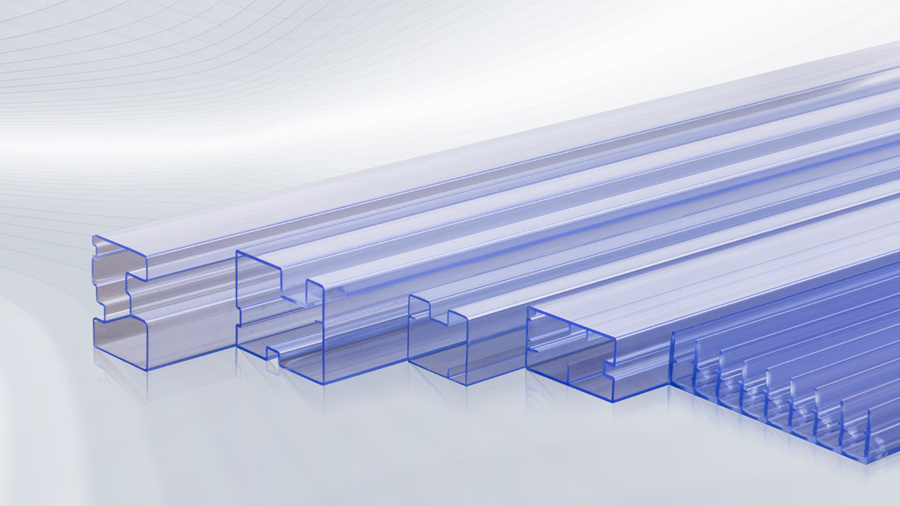

Injection Products

High precision molded with a tolerance of 0.05 mm at key dimensions. Support on-demand production using ABS, PS, PBT, PP and other materials.

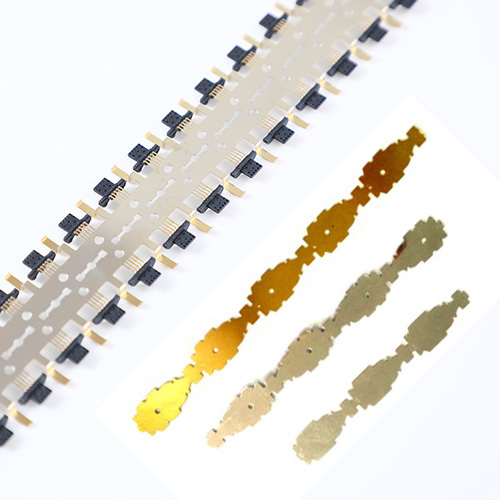

Stamping Products

Leading mold design and manufacturing technology in China and satisfying quality control processes, to ensure the precision of each component and provide our customers with the best production solutions.

Connector

The precision connector components manufactured by our company are widely used in industrial equipment and household appliances, and our automobile plastic parts are produced in strict accordance with TS16949 standards.

Qualifications

We have passed ISO9001 quality system certification, ISO14001 environmental management system certification and TS16949 quality management certification for automotive industry. We promise to sincerely serve every customer with the business philosophy of “first-class quality and industry leadership”.

Qingdao Haitai Steel-Plastics Products Co., Ltd., was established in

Total investment since establishment

Products of 5 categories, covering the electronic packaging material industry

Annual total sales

subsidiaries

About Haitai

Qingdao Haitai Steel-Plastics Products Co., Ltd. is located in the beautiful coastal city of Qingdao, covering an area of 13,000 square meters, with a total investment of 80 million RMB. We are a comprehensive electronic packaging material manufacturer covering five categories: extrusion, emboss, injection, stamping, and connectors.

Since its establishment more than 20 years ago, our company has carried out win-win cooperation with many Fortune 500 companies, such as TE, Tokai Rika. We provide global customers with integrated customer service solutions for the whole process of product development, manufacturing, service, etc., and our products are exported to more than a dozen different countries including Japan, Germany, India, Italy and Thailand. Our company has strong R&D ability, first-class production technique, high-standard quality control capability, as well as many high-end talents who have been in the industry for many years to sincerely provide the best quality services for each customer.

Customer Message

News Center

What do you need to know about customizing IC packaging tubes

The customization of IC packaging tubes requires the following four aspects of information: 1. Selection of tube material; 2. Dimensional drawings of the components or physical objects; 3. Length of the tube; 4. Selection of plugs.

Recently, the pins of some connectors of our Swedish customers are susceptible to external forces, especially during transportation. Without a good packaging, the connectors can be highly damaged.

Why some customers feel that the mold cost of extrusion packaging tube is high?

Some customers feel that the mold cost of extrusion packaging tube manufacturers is a little expensive. Please let me show you why with our 20 years of experience in producing non-jamming packaging tubes. So why our extrusion packaging tube molds are expensive? First, all molds have a service life. Do you think that the mold made of ordinary iron material is more durable than that made of steel material? Of course, steel material is preferred. We select steel materials that have rust prevention and wear resistance. Many manufacturers have opened their molds with us, and after being used for six or seven years, the molds still look like new ones! Second, our mold size requirements are precise and the error of the produced tube is very small. After the mold is ready, we first test it, polish it, and load it onto the extruder. Then we test the accuracy of the size of the produced tube to make a decision on whether to repair the mold and to ensure consistency with the packaging tube solution, basically within a tolerance of 0.01 mm. We carry out regular maintenance on our moulds to ensure that the quality of our products is always consistent.

Qingdao Haitai Steel-Plastics Products Co.,Ltd.

Tel:+86-532-88563866

E-mail Address:huangwz@qdhaitai.com

Address:289 Taoyuanhe 2nd Road, Jimo, Qingdao, Shandong, China

QR code for business consultation

Copyright © 2023 Qingdao Haitai Steel-Plastics Products Co., Ltd.SEO Business License

Language

Language